Description

The main function of this machine is to test the burst strength of materials such as base paper, corrugated paper, leather, fabrics, synthetic leather, etc. It is an automatic type capable of automatic clamping, automatic compensation calculation, and automatic judgement for shutdown at the breakpoint. It also features a mechanism that can automatically detect rubber diaphragm pressure when there is no sample, greatly reducing the risk of rubber diaphragm rupture due to improper manual operation. The machine complies with standards and can automatically calibrate the rubber diaphragms based on hydraulic conditions, eliminating the need for periodic use of aluminium foil for calibration. This ensure more timely and accurate presentation of pressure data while reducing the cost of aluminum foil as consumables.

Conform to Standards

- ASTM D2210

- ISO 2759

- GB/T 6545

- JIS P8112

- JIS L1018

- TAPPI T403

- JIS L1096

- ASTM D3786

- TAPPI T810

- TAPPI T807

Industry

Textile Industry, Paper Industry, Packaging Industry

Catalog Download

QC-116D Automated Mullen Burst Tester

Specifications

Type

High Pressure/ Low Pressure/ Textile

Machine Speed

20~200ml/min

Pressure Display

Digital Display

Unit

Bar, MPa, kPa, PSI, mmAq, mmHg, Kgf/cm2

Capacity (Kg/cm2)

75 Kg/cm2

Compensation Value

Automatic Calculation

Test Speed

High Pressure:170 ± 15 ml/min

Low Pressure:95 ± 5 ml/min

Textile:98 ± 4 ml/min

Platen Diameter (upper)

High Pressure:31.5 ± 0.05 mm

Low Pressure:30.5 ± 0.05 mm

Textile:30.5 ± 0.05mm

Platen Diameter (Lower)

High Pressure:31.5 ± 0.05 mm

Low Pressure:33.1 ± 0.05 mm

Textile:30.5 ± 0.05mm

Dimension (W)x(D)x(H)

43 x 57 x 68 cm

Weight (around)

85 Kg

Power Supply

c 110~240VAC, 5A

Accessories

Rubber diaphragm-Low Pressure

Rubber Diaphragm serves as a vital component in burst testing setups. Positioned beneath the specimen pressure plate, it plays a crucial role in the application of pressure during tests. When pressure is exerted, the diaphragm, filled with glycerin, expands, ultimately leading to the rupture of the specimen.This is a test consumable that may become soiled, worn, or damaged through random usage of the platform. Replacement may be required as necessary.

The low-pressure rubber membrane is suitable for pressures ranging from 0 to 10 kgf/cm².

Rubber diaphragm-High Pressure

This accessory for the bursting strength test is placed under the test specimen plate. After pressurization, the glycerin will hold up the rubber film and then break the test specimen.

This is a test consumable that will be fouled, fatigued or broken when used for a period of time and will need to be replaced if necessary.

Note: High pressure rubber film is applicable to the range 6~75kgf/c㎡

Related Machines

Related Services

-

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

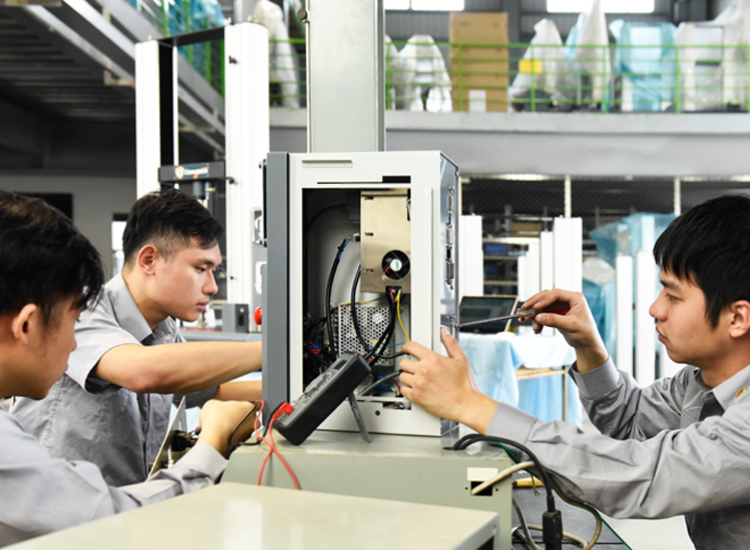

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE